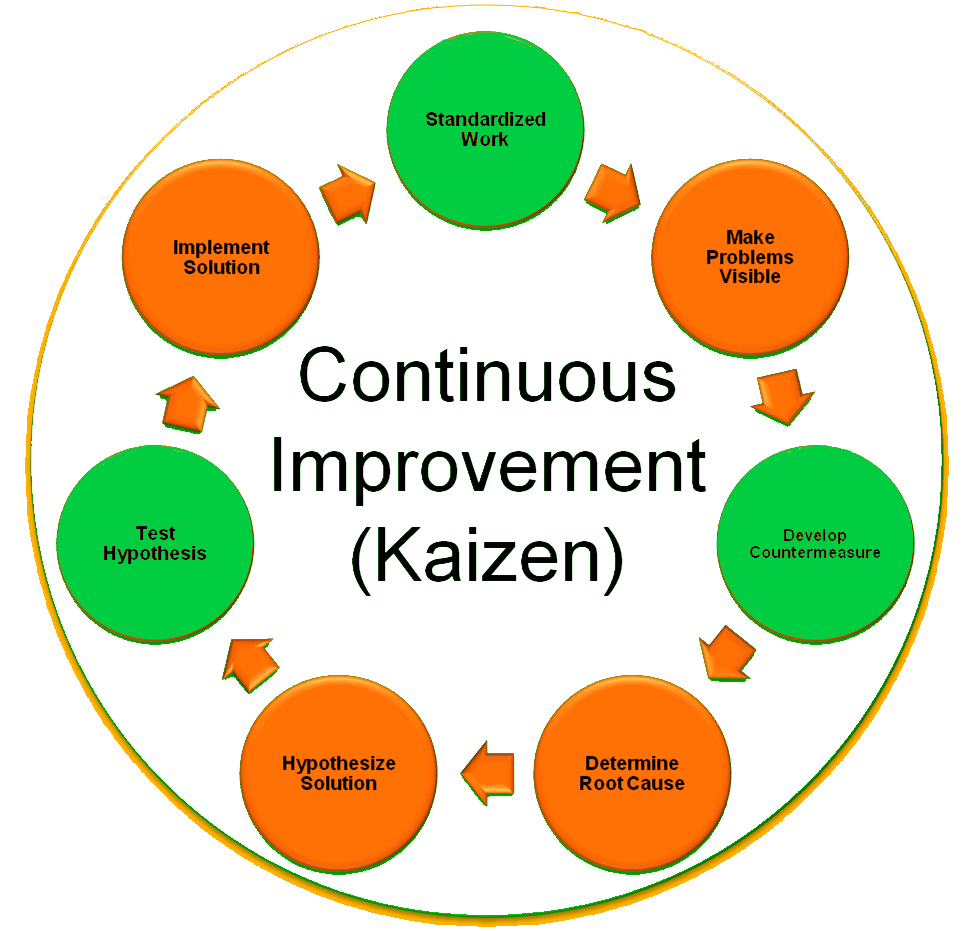

In the 1930’s engineer Walter Shewhart developed the Plan-Do-Study-Act (PDSA) cycle of work. This inspired Taiichi Ohno in the late 1940’s with the idea of kaizen, a manufacturing mindset of continual, incremental improvements. It is credited with the success of Toyota. Now the concept is used in many businesses.

The word has two parts, kai and zen. Kai means change and zen means good. Change for good. Often kaizen is translated as “continuous improvement”. Increasing efficiency and decreasing waste is key to kaizen. As is enabling discipline and being proactive.

On the surface kaizen does not fit with ease into bonsai. Often quick, dramatic change is necessary in bonsai work, which is the antithesis of kaizen.

But consider a few alignments.

On the garden level, we’re all busy folks. Many of us have missed decandling a black pine at some point in our bonsai journey, and we know it sets us back five years. Same with waiting too long to repot, which can lead to branch death. A good winter activity is taking a hard look at what worked the year before and improving what didn’t, the first steps of kaizen.

On the tree level, wiring is a task with a rote muscle memory that improves with repetition. Our body is the tool. We might focus on the product—a bonsai—but we’re also improving the tool itself each time we wire a tree.

A young tree might be seen as a multi-stage product, like a drawing of a tree that takes ten years before a bonsai appears. Each year brings incremental maturation of a goal.

The kaizen methodology is maybe best suited to mature bonsai, where the form is already there. We’re not recreating this bonsai every year, we start with the same detailed structure we had the year before.

We often hear that a bonsai is never finished. A bonsai grows, so it’s never finished. And yet improvement is not a given. A bonsai may improve, it may stay the same, or it may degrade.

Usually we do not imagine a bonsai as a number of people working toward a common goal, as one might in a factory. But if we take the long view, bonsai is not out of alignment with communal effort.

So while kaizen cannot give a way forward in terms of bonsai technique, it may offer inspiration. A bonsai can always improve in the small details. Kathy Shaner, the first westerner to apprentice bonsai in Japan, said that rather than taking a big swing at a bonsai every year, nudge it along with little swings and soon you’ll be far ahead. Her mascot was a turtle.

A common criticism of kaizen is the challenge of momentum. It can be hard to maintain initial progress if it’s incremental and hard to see. It’s like an 401K in the early years, nothing seems to happen. But an essential practice in bonsai is to keep at it, and not drop the ball.

A car is finished when it leaves the factory, but the process that made it isn’t finished. The process can be nuanced and improved to make a better car. Learning bonsai technique is the first step in improving those techniques to make (and maintain) better bonsai.